|

Rotameters - | Glass Tube Rotameter | Glass Tube Rotameter with Transmeter | Metal Tube Rotameter | Metal Tube Rotameter with Transmeter | By - Pass Rotameter| Acrylic Rotameter | Low Flow Rotameter | Low Flow

Rotameter with DP Regulator | GTR with Flow Switch

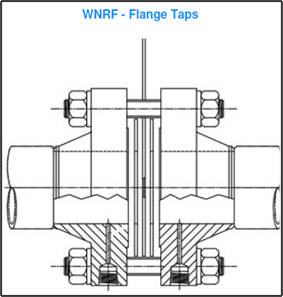

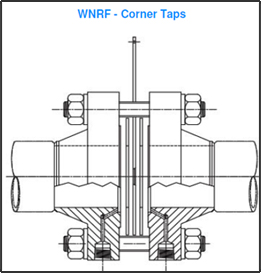

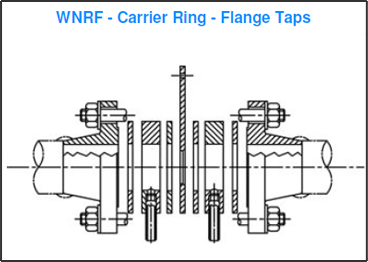

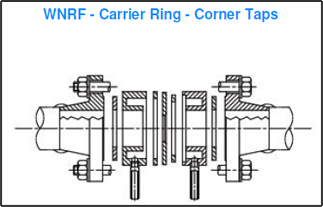

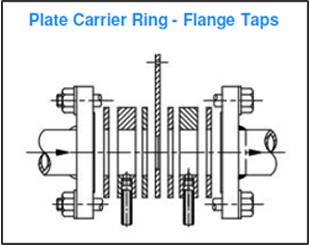

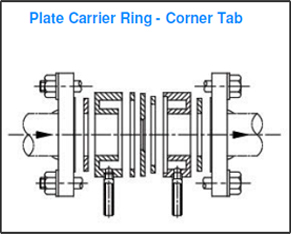

Orifice Plate and Flange Assembly- | Co-centric Orifice Plate Eccentric Orifice Plate | Segmental Orifice Plate | Restriction Orifice Plate | Ring Type Joint Orifice Plate | Universal Orifice Plate | Multistage Orifice Plate | Orifice Plate | Orifice Assembly | Carrier ring Assembly with Transmeter mounting Pad | Integral Orifice Assembly with Meter run & 3 Way valve manifold | Orifice based Steam Flow Meter | Electromagnetic Flow Meter - | Full Bore Electromagnetic Flow Meter | Full Bore Electromagnetic Flow Meter Wafer Type | Full Bore Electromagnetic Flow Meter Sanitary Grade | Electromagnetic Flow Meter - Insertion Type | Coriolls Mass Flow Meter | Vortex Flow Meter | Clamp -on Ultrasonic Flow Meter | Flow Indicators - | Flow Indicating Totalisers | Sight Flow Indicators (Full View) | Window Type Sight Flow Indicators | Transpertant

Level Indicators | Reflex Level Indicators | Magnetic Level Indicator | Float and Board Level Indiactors | Top Mounted Level Indicator| Top & Side Mounted Level Switches |Tubular

Level Indicator | Sight Flow Indicator

Manometers : | U Tube Manometer | Inclined Manometer | Single Limb Manometer |

Transmiters : Pressure Transmeters | Differential Pressure Transmeter | Y Type

Strainers | T Type Strainers |

Basket Type Strainer | Basket Type Strainer - Simplex Strainer | Basket Type Strainer - Duplex Strainer | |

| Home | About Us | Products |Certifications | Clients | Contact Us | Enquiry | Designed & Hosted by : MID | Promoted by : GID |